Simulation Services

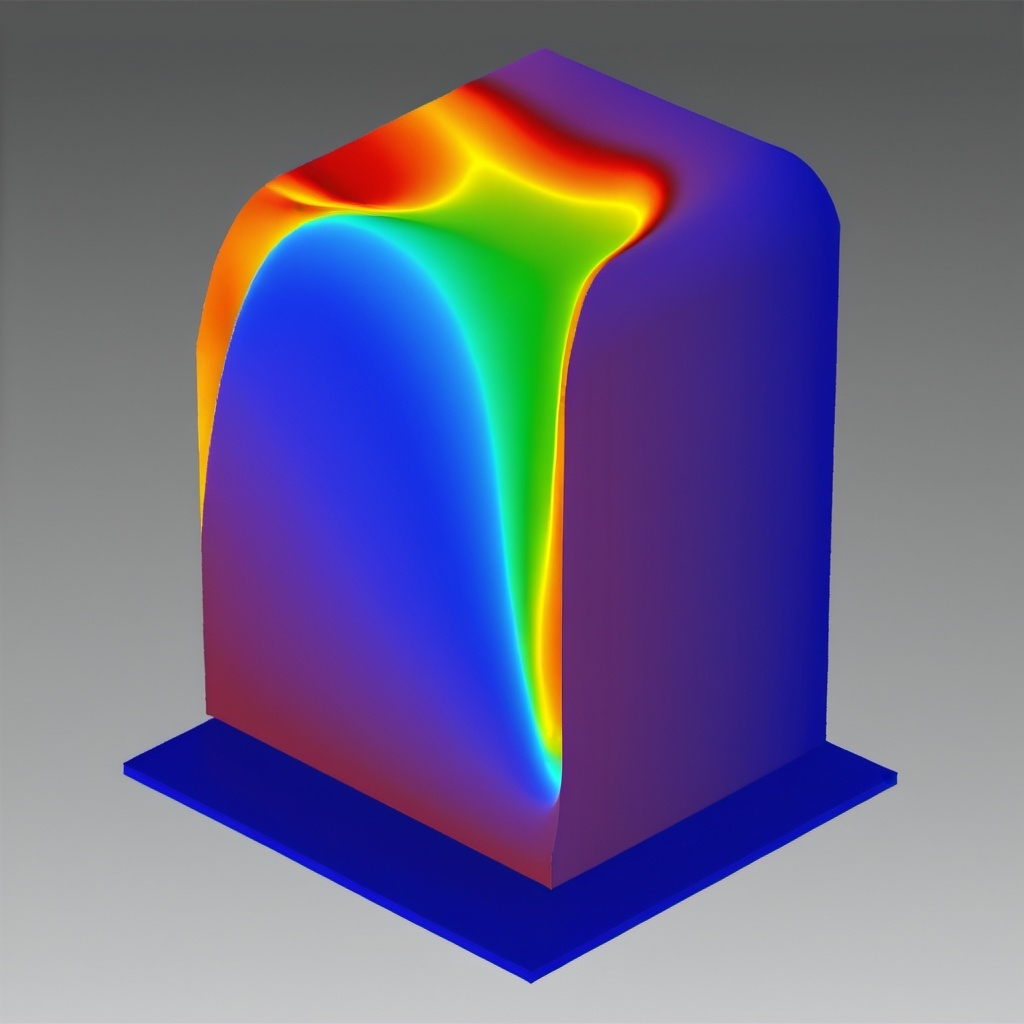

Our services virtually span the entire scenario of simulations currently possible in the thermo-structural domain, as listed below.

Static

- Linear and non-linear elastic

- Elastic-plastic (using different material models, from the simple elastic-perfectly plastic one to the actual stress-strain curves)

- Contacts among parts and self-contact

- Linear buckling

- Post buckling

- Bonding damage&failure

- Ductile damage&failure

Dynamic

- Modal

- Implicit transient

- High speed impacts (such as crash & bird strike)

- Frequency and spectrum response

- Time history

Thermal

- Steady state

- Transient

- Coupled thermo-structural

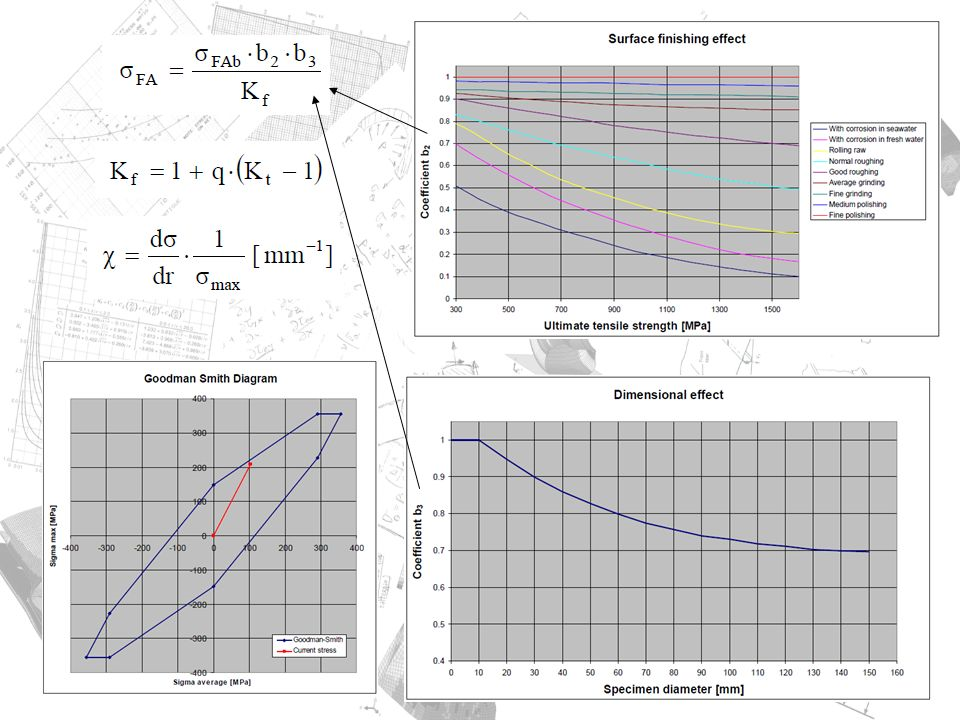

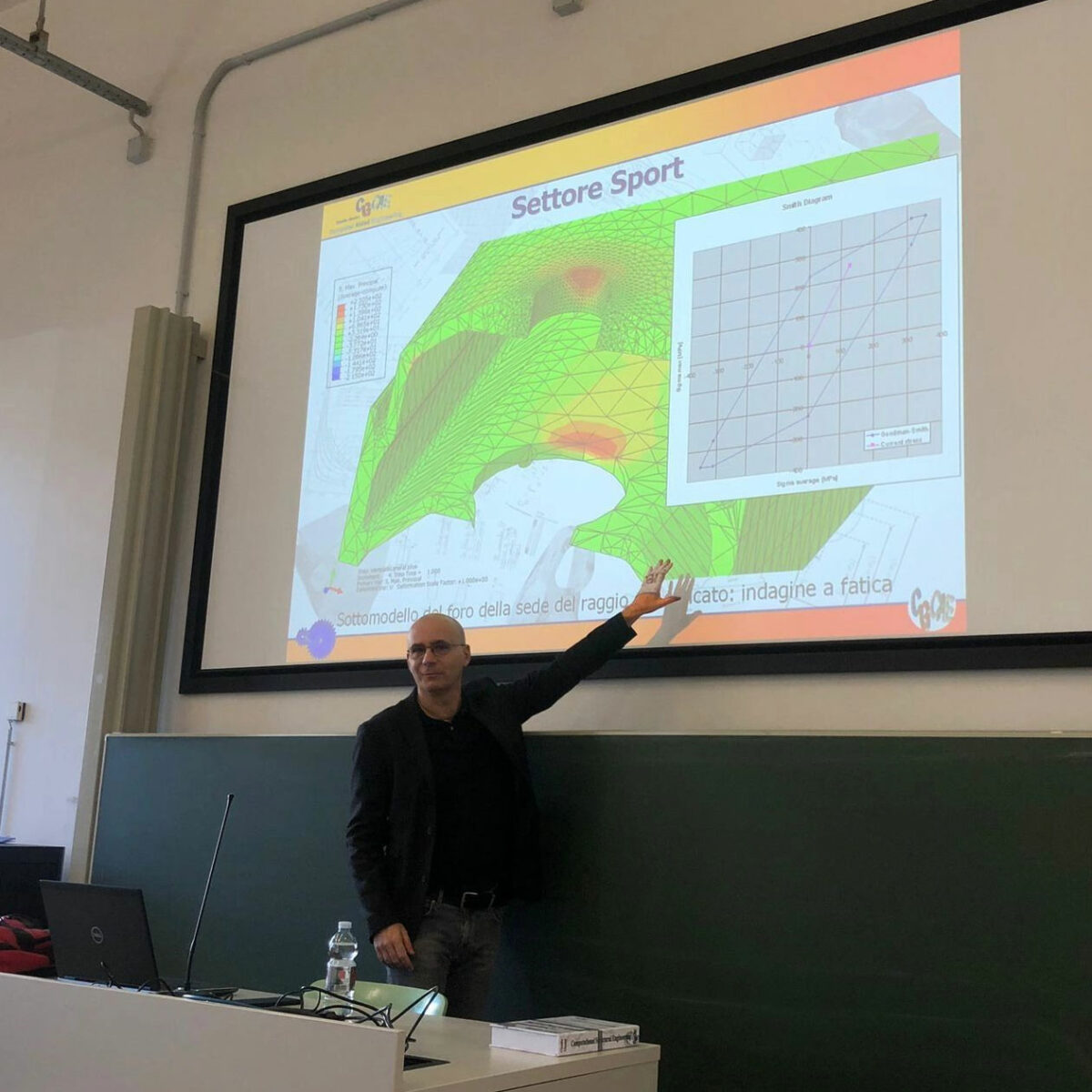

Detailed Assessments

- Fatigue (with different criteria)

- Bolted and riveted connections

- Welded connections

- Stress linearization (according to ASME or RCC-MR rules)

Materials

- Isotropic homogeneous (steel, aluminium, titanium, magnesium)

- Composites (carbon, glass, Kevlar fibres)

- FRP (plastics reinforced with short fibres)

- Hyperelastic (rubbers)

- MMC (Metal Matrix Composites)

FEM Trainings

- Basic: linear, modal and buckling analyses

- Advanced I: non linear static: large deflections, contacts, material plasticity

- Advanced II: composites & hyperelastic

- Advanced III: dynamic implicit and explicit

CG CAE has its own licenses for the Dassault Système ABAQUS software, the renown code that can deal with the many different problems posed by engineering practice.

On top of that, we can use other commercial software, like ANSYS, NASTRAN and the ALTAIR suite.

Finally, at CG CAE we do believe in the utility of open source software and, whenever possible, we use CalculiX together with PrePoMax and MecWay to prepare, solve and post-process our models.

Privacy Settings

This website uses cookies to improve your experience while you navigate through the website.

View the Cookie Policy View the Personal Data Policy

Google Analytics is a web analytics service provided by Google Ireland Limited ("Google"). Google uses the collected personal data to track and examine the usage of this website, compile reports on its activities, and share them with other Google services. Google may use your personal data to contextualize and personalize the ads of its advertising network. This integration of Google Analytics anonymizes your IP address. The data sent is collected for the purposes of personalizing the experience and statistical tracking. You can find more information on the "More information on Google's handling of personal information" page.

Place of processing: Ireland - Privacy Policy

Additional consents: